What is the difference between cast iron and ordinary iron?

Cast iron is a general term for alloys mainly composed of iron, carbon, and silicon. In these alloys, the carbon content exceeds the amount that can be retained in the austenite solid solution at the eutectic temperature.

1. Studying different histories

Iron: Humans first discovered iron in meteorites that fell from the sky. Meteorites contain a high percentage of iron (90.85% iron in iron meteorites) and are a mixture of iron, nickel, and cobalt. Archaeologists once discovered small axes made of meteorite iron in ancient tombs;

As early as 4000 years ago in ancient Egypt, the religious scriptures hidden in the pyramids of the Fifth to Sixth Dynasties recorded that the thrones of important statues such as the Sun God were made of iron. Iron was considered the most precious metal with mystique at that time, and the Egyptians simply called it the "heavenly stone".

Cast iron: Smelting iron ore into iron. In January of the second year of the Heping reign of Emperor Cheng, the iron official of Pei County cast iron. The iron could not be cast down, and it rumbled like thunder and the sound of drums

In the biography of Yang Jin in the "History of the North," it is written: "Digging deep into springs, digging wide underground tunnels, hidden soldiers gushing out, setting up furnaces and casting iron, and holding them to irrigate thieves. The thieves then reported to each other, saying, 'Do not fear the strong city, only fear the iron star of Yang Gong.'" In the poem "Reflections on the Red Boat Journey to Danyang" by Chen Weisong of the Qing Dynasty, it is written: "Cast iron has become an eternal mistake, and reading has brought shame to the people

2. Different preparation methods

Iron: The preparation of elemental iron is generally carried out by smelting method. Using hematite (Fe2O3) or magnetite (Fe3O4) as raw materials, it reacts with coke and co solvents in a melting furnace. The combustion of coke produces carbon dioxide (CO2), which reacts with excess coke to produce carbon monoxide (CO). The reaction between carbon monoxide and iron oxide in the ore produces metallic iron.

Adding CaCo3 at high temperature generates CaO to remove SiO2 from iron ore, resulting in CaSiO3 (slag).

During the smelting process, the lower part of the furnace body is filled with coke, which is called bottom coke. On top of the bottom coke, there are alternating batches of iron materials (pig iron, scrap steel, recycled materials, ferroalloys, etc.), coke, and fluxes (limestone, fluorite, etc.). By blowing air, the bottom coke is strongly burned, and the high-temperature furnace gas produced rises along the height direction of the furnace body, melting the layer of iron material above it.

3. Different uses

Iron: used in pharmaceutical, pesticide, powder metallurgy, thermal hydrogen generator, gel propellant, combustion active agent, catalyst, water cleaning adsorbent, sintering active agent, powder metallurgy products, various mechanical parts products, cemented carbide materials products, etc.

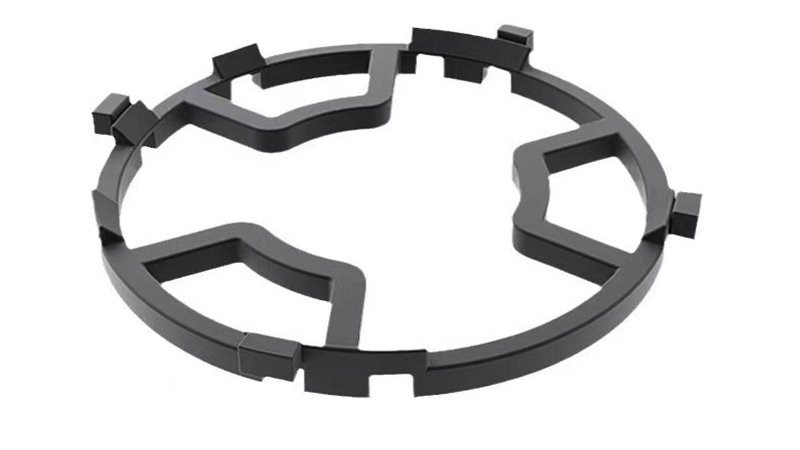

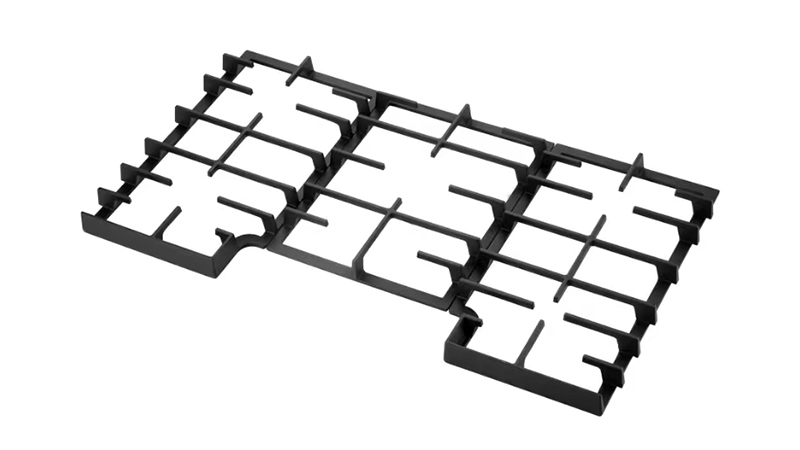

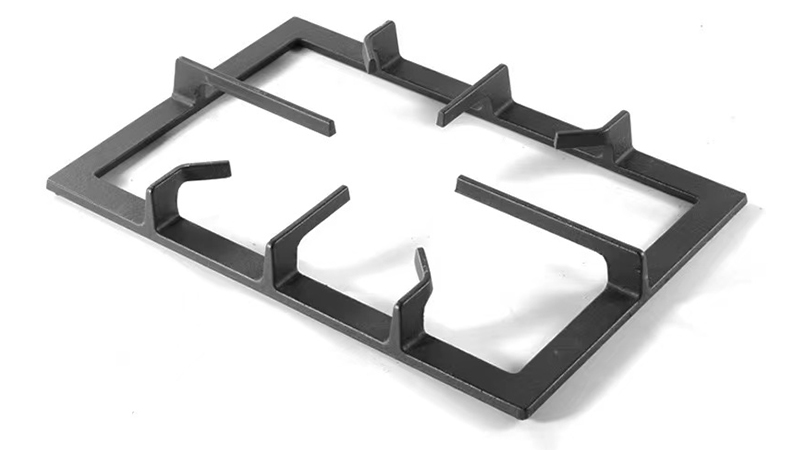

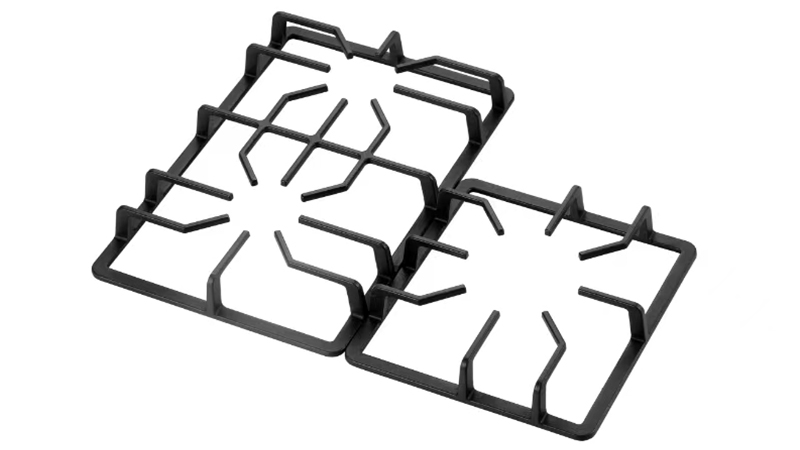

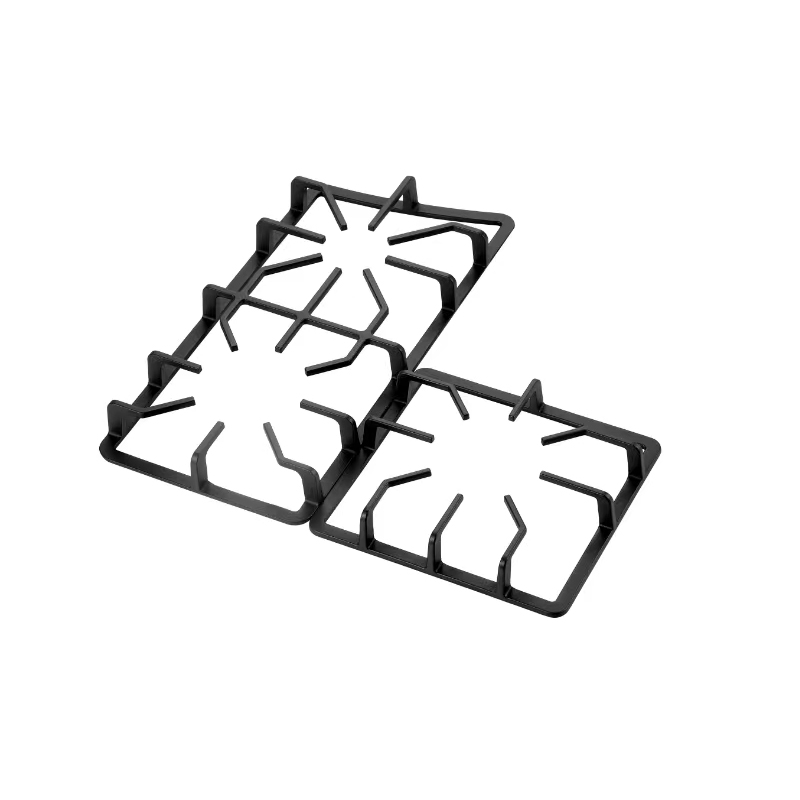

Cast iron: Castings have a wide range of applications, including hardware and the entire mechanical and electronic industry, and their use is constantly expanding. Specifically used in industries such as construction, hardware, equipment, engineering machinery, machine tools, ships, aerospace, automobiles, locomotives, electronics, computers, electrical appliances, lighting fixtures, etc.