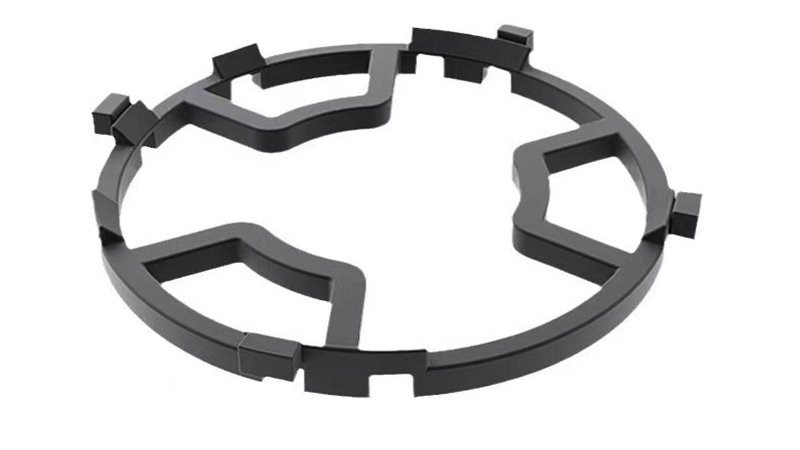

How should the overall process flow of the cast iron platform be arranged

The process road planning of cast iron platform is the overall layout of the process flow, and the operation is the selection of processing methods for each side, confirming the processing sequence of each side, as well as the number of processes, etc.

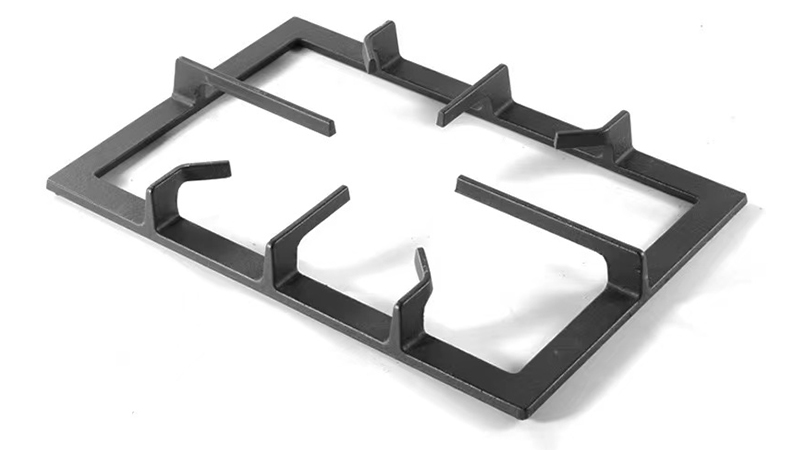

Cast iron platform machining reference surface: During the machining process, the cast iron platform should be machined as a positioning reference surface to provide a reference for subsequent processes as soon as possible. It's the benchmark from before.

The cast iron platform is divided into three stages: rough machining, semi precision machining, and precision machining, which require high processing quality for the surface. Prioritizing processing quality is beneficial for the rational use of equipment, facilitating the organization of heat treatment processes, and identifying defects in raw materials.

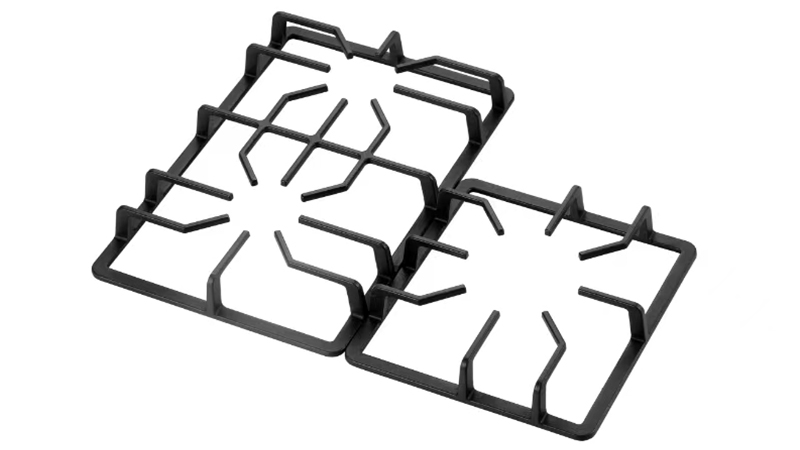

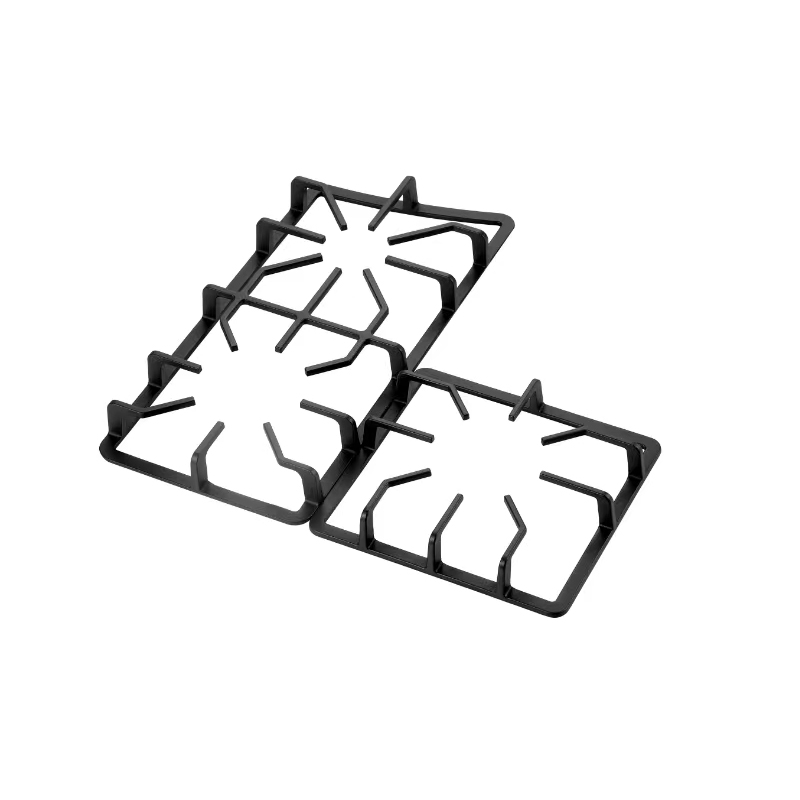

Cast iron platform

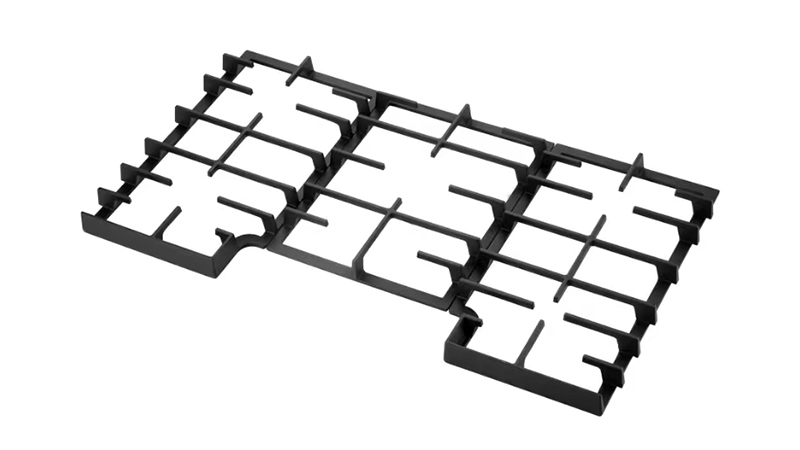

Front and rear holes of cast iron platform: Parts such as boxes, brackets, and connecting rods should be machined flat first and then drilled. By positioning the machining hole through a plane, the accuracy of the orientation between the plane and the hole is improved, which facilitates plane machining.

Welding accuracy, the cast iron platform has undergone rough and fine machining separately. The rough machining amount of pig iron platform is large, and the workpiece is subjected to high cutting force, clamping force, heat generation, and significant work hardening phenomenon on the machined surface. There is also a large internal stress in the workpiece. When rough machining is carried out continuously, the precision of the precision machined part is lost due to the redistribution of stress. For some precision machining parts. After rough machining and before precision machining, low-temperature annealing and aging treatment processes should be organized to address internal stress.

Reasonable selection of cast iron platform equipment. Rough machining involves cutting off most of the machining allowance and does not require machining accuracy. Therefore, rough machining should be carried out on machine tools with high power and low precision, while precision machining should be carried out on machine tools. Performing rough and fine machining separately on different machine tools can fully utilize the production capacity of the equipment and extend the service life of the machine tools.